Johnson-manu(shenzhen) Co.,Limited

Building E, NO. 49 Xin’er zhuang cun Road

Shajing Town, Bao’an District,Shenzhen,China

Mould Design

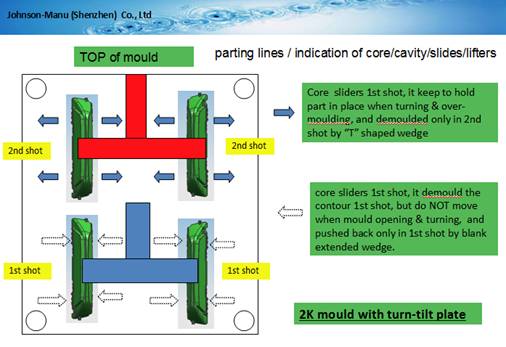

We can be very accurate and reliable design layout that customers realize what they want. Our designers are highly skilled team not only familiar with Hasco/DME parts,but also own a extensive design experience for various moulds,especially 2K mould. The English communication can be very professional + highly-effective through our project managers, who are all born from designers.(oral+written)

We have been training by our customers,but also have been training our custumers by representing a reliable and secure method/direction. We are still design innovation. We believe that our technology + service will get your trust and support.

Design for Manufacturing(DFM)----troubleshoot any improper design

Design for Manufacturing(DFM)----troubleshoot any improper design One stop solution—ability to take products from concept to production

One stop solution—ability to take products from concept to production Strong engineering team

Strong engineering team 3D solid mould design with UG NX 7.0

3D solid mould design with UG NX 7.0 Mouldflow simulation

Mouldflow simulation

Sophisticated mould concept with a fully proactive & reliable solution

Design for Manufacturing(DFM)

draft analysis

draft analysis sink mark analysis

sink mark analysis improper design causing sharp steel

improper design causing sharp steel improper design failing to demould

improper design failing to demould design optimization to simplify parting line&mould structure

design optimization to simplify parting line&mould structure review 2D part drawing with tolerance/surface finish/gate/parting line/other notes.

review 2D part drawing with tolerance/surface finish/gate/parting line/other notes. review material datasheet to findout shrinkage,color,injection parameters.

review material datasheet to findout shrinkage,color,injection parameters. review injection machine datasheet

review injection machine datasheet review other written/oral requests from our customers

review other written/oral requests from our customers

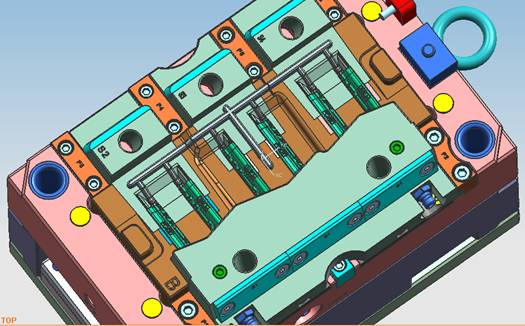

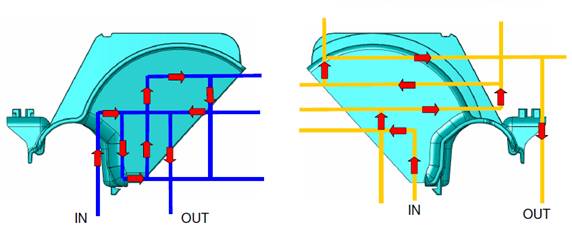

Stringent cooling advice to minimum deformation and cycle time

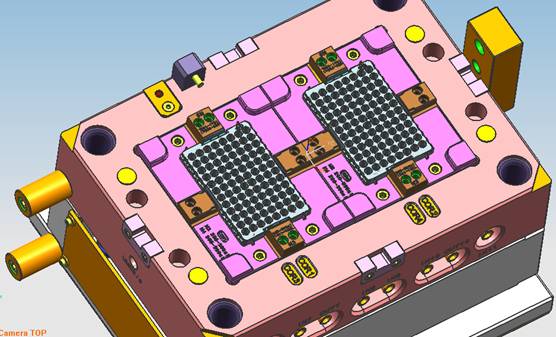

3D solid mould deisgn with UG NX 7.0

further optimisations with a thorough consideration.

further optimisations with a thorough consideration. tolerance adjustment as per 2D part drawing

tolerance adjustment as per 2D part drawing all part colored and identified ---easy review + followup

all part colored and identified ---easy review + followup strictly follow the standard and style of each customer

strictly follow the standard and style of each customer review process manufacturing capability to 3D design

review process manufacturing capability to 3D design

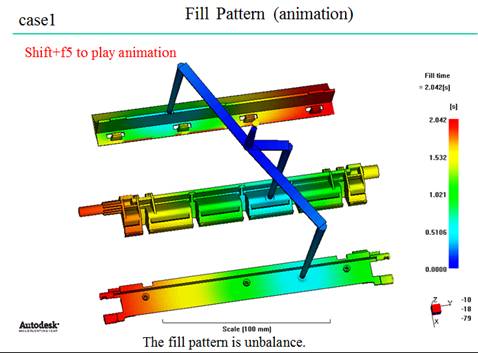

Flow analysis , deformation analysis

Deformation analysis showed part deformation in X/Y/Z direction with 2 options of gate position,then we can know proactively which option is better,and do further optimizations accordingly.

Flow analysis can help us find a optimal gating solution on gate position,gate size and runner size, especially for family mould.